Good Food Conference 2023: Meet the MarqMetrix Team

We invite you to join us at booth 308 on September 18-20 in San Francisco, where we will demonstrate how our Raman technology can revolutionize alternative protein analysis.

MarqMetrix to Showcase SAF Solutions in Minneapolis

Mark your calendars for August 29-30 and make sure to stop by booth 118 to discover the cutting-edge solutions that MarqMetrix brings to the sustainable aviation fuel landscape. As a leading provider of advanced analytical solutions, MarqMetrix is excited to showcase its groundbreaking solutions for the SAF industry. More details.

MarqMetrix Exhibiting at Carbon Capture Technology Expo in Houston

Attending CCTE on June 28-29? We invite you to join us at Stand 1720, where we will demonstrate how our Raman technology can revolutionize carbon capture processes.

Explore the Future of Alt Proteins with MarqMetrix at the Future Food Technology Alternative Proteins Summit

Discover the cutting-edge Raman technology of MarqMetrix at the Future Food Technology Alternative Proteins Summit in New York City. As a leading provider of advanced analytical solutions, MarqMetrix is excited to showcase its groundbreaking solutions for the alternative protein industry. Join industry professionals, researchers, and innovators on June 27-28 to explore the latest advancements in this rapidly evolving field. More details.

MarqMetrix to Showcase Revolutionary Raman Technology at 2023 IFPAC Trade Show

The MarqMetrix team will be on-site at the IFPAC 2023 conference on June 4-7 in Bethesda, MD. Visit booth 409 to see the latest Raman technology and meet the team.

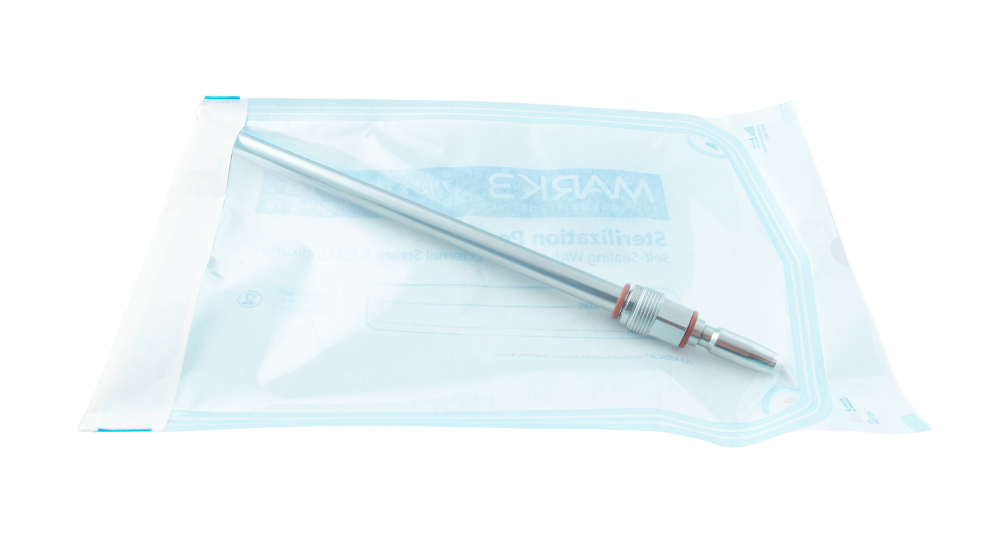

Introducing the New Single-Use BioReactor BallProbe®

Designed to be sterilized, the Single-Use BioReactor BallProbe® ensures accurate and repeatable Raman measurement of liquids and solids without compromising your batch’s purity. Made from sanitary finished (15Ra) 316 stainless steel and high-purity sapphire optics, this single use Raman probe is engineered to meet the requirements of the bioprocessing industry. More details.

Analyzer Technology Conference 2023

The MarqMetrix team will be on-site at the Analyzer Technology Conference in Galveston, TX, from April 17-21. Visit Booth 215 to meet the team and see the latest process Raman innovations for the energy industry.

Webinar: Enhancing Analytical Methods – Raman Spectroscopy as an Addition to your Current

Analytical Pipeline

Save the date for our upcoming webinar on April 26 at 11am EDT (8am PDT, 5pm CET)! Raman spectroscopy techniques offer numerous benefits in analytical measurement, particularly in the energy sector. Gas chromatography [GC] and Raman spectroscopy have a wide array of applications in this space, including petroleum analysis, biofuels, and natural gas analysis. Join us to learn how to learn how Raman can complement existing GC analysis to deliver rapid, actionable analytical measurement. Register here.

Implementing Process Analytical Technology

MarqMetrix Founder & CEO Brian Marquardt tells PharmTech that the adoption of Raman in continuous manufacturing is increasing due to applicability and affordability.

“Recent developments have made Raman easier to use, more stable in calibration, and smaller in size [compared to earlier Raman technology]. These innovations have also made Raman scalable by reducing the cost to acquire and implement the technology,” he explains

Read more here.

Simplifying Oil & Gas Predictive Modeling to Cut Costs

“Chemometrics is a way oil and gas companies can turn data into dollars and it is becoming the de facto method for processing analyzer instrument output. The information can then be used to fast track the delivery of products to the market, reduce processing costs and maximize value,” our Director of Chemometrics Thomas Dearing tells New Equipment Digest. Read more here.

Raman Spectroscopy: Reducing the Time to Verify Gasoline Blends

Raman spectroscopy is quickly gaining traction as a highly efficient, accurate and reliable solution offering the potential to transform the speed and logistics of sampling gasoline blends so that refineries can get their product to market faster.

In this article, refineries like U.S. Oil & Refining in Tacoma, Washington discuss how they are increasingly turning to advanced Raman spectroscopy analyzers that can produce results in less than a minute using established models, instead of the two to three hours using an Octane engine. Read more here.

In-Line Raman Analysis of Fatty Acid Features in Salmon Fillets

Read why our collaborators at the Norwegian Institute of Food, Fisheries and Aquaculture Research (Nofima) chose Raman spectroscopy for a study focused on in-line analysis of fatty acid features in salmon.

Read more here.

Raman Spectroscopy: The New Standard in Oil, Gas and Petrochemical Laboratories

Solid-state Raman spectroscopy is becoming an essential analytical tool in O&G and petrochem testing labs. Read why laboratories are choosing Raman to measure the chemical composition of raw materials and the consistency of processed products. Full article available here.

MarqMetrix to Exhibit and Host Technical Talks at

Gulf Coast Conference

MarqMetrix will exhibit and host two technical talks at Gulf Coast Conference in Galveston, TX on October 10-12. Visit booth 1216 to see the latest model of the All-In-One.

Learn more about this event here.

Raman Webinar: Solid-State Raman – An Ideal Pat Tool for Pharma & Biopharma Manufacturing

MarqMetrix is hosting a 30-minute webinar on June 29, 2021, covering why Raman is the ideal PAT tool for the biopharma and pharma industries.

Learn more about this online event here.

Raman for Pharma: Detecting Processing Fingerprints

MarqMetrix Founder & CEO Brian Marquardt explains how Raman spectroscopy delivers real time, non-destructive process insights for critical process parameters to monitor pharmaceutical manufacturing in the latest issue of Pharmaceutical Manufacturing. Read more here.

MarqMetrix to Virtually Attend IFPAC 2021, Present Raman Solutions for Food & Beverage, Oil & Gas, and Biopharma Industries

MarqMetrix Founder & CEO Brian Marquardt will highlight how Raman spectroscopy offers businesses actionable and real-time compositional insights for quality control and product development during the IFPAC 2021 Interactive Virtual Event. The presentations, occurring on March 1, 2, and 4, will cover Raman solutions for the food & beverage, oil & gas, and biopharmaceutical industries.

More details are available here.

Raman Spectroscopy: Bringing Inline Analysis to Production

MarqMetrix Founder & CEO Brian Marquardt, Ph.D, and MarqMetrix Application Specialist Bharat Mankani, Ph.D, discuss the benefits of Raman spectroscopy as an inline process analysis tool in their latest article for Spectroscopy. Read more here.

MarqMetrix to Attend SciX 2020, Founder & CEO Brian Marquardt Presenting Virtually on Oct. 15

In his virtual presentation at 10 am EST on October 15, 2020, Brian Marquardt, Ph.D will discuss how MarqMetrix’s innovations in hardware, sampling, and data analysis can drive success in bioprocesses.

More details are available here.

Online Learning Sessions with MarqMetrix

MarqMetrix is offering 30-minute online educational sessions covering our accessible Raman solutions for process analysis. Our webinar series will take a deep dive into Raman’s advantages for the BioPharma and Pharma industries.

Learn more about this online event here.

MarqMetrix to Attend IFPAC 2020, Participate in Process Raman Symposium on Feb. 24

MarqMetrix will address the challenges impacting the adoption and use of Raman spectroscopy in biochemical applications at the IFPAC 2020 Process Raman Symposium on February 24 in Washington, D.C. MarqMetrix’s founder, CEO and Chief Technical Officer, Brian Marquardt, Ph.D., will chair the session. While at the show, visit us in booth 409 on February 23-26 to meet the team and see our products in action. Read more here.

Real-Time Lubrication Intelligence System

Sensei™ Real-Time Lubrication Intelligence was a development between two companies: Trico Corporation and MarqMetrix Inc., combined 100 years of industrial knowledge with the power of sensor development and cloud analytics. The oiler marks the first of numerous devices to be released on the Sensei™ platform.

Learn more about Sensei on Maintenance Technology.

The Realities of Undergrad Raman

By Brian Marquardt and Giora Proskurowski, MarqMetrix and Evan Friedman, Hellma

The Problem

Raman spectroscopy is a great tool for quality control, product verification and process monitoring – but a lack of staff with appropriate Raman experience often rules out its use. Undergraduate chemistry students rarely get exposure to – never mind experience with – Raman spectroscopy. Our research suggests that when it comes to teaching the technique, price is the primary barrier, so we set out to create a low-cost, capable Raman laboratory system that is suitable for both teaching and research at any level.

Read more on The Analytical Scientist.

MarqMetrix Introduces Sensei Real-Time Lubrication Intelligence System with Trico Corporation

For Immediate Release

MarqMetrix Introduces Sensei Real-Time Lubrication Intelligence System with Trico Corporation

Seattle, WA— May 3, 2017 — MarqMetrix® is pleased to announce a partnership with Trico Corporation, a leading provider of lubrication management solutions, in introducing Sensei™, a real-time lubrication intelligence system. Sensei, believed to be the first system of its type, wirelessly transmits oil level and ambient air temperature to a customizable, web-based dashboard. As a result, users gain real-time input on machine status and maintenance requirements. Sensei can:

- Reduce inspection time from hours to minutes per week.

- Reduce requirements for personnel to visit difficult- or dangerous-to-access areas.

- Help avoid downtime by providing alerts and warnings.

- Enable organizations to operate more efficiently by performing proactive, data-driven maintenance.

Sensei™ Real-Time Lubrication Intelligence was a development between two companies: Trico Corporation and MarqMetrix Inc., combined 100 years of industrial knowledge with the power of sensor development and cloud analytics. The oiler marks the first of numerous devices to be released on the Sensei™ platform.

“We’re thrilled to finally announce that Sensei™ is now available through our partnership with Trico Corporation,” said Brian Marquardt, Founder and Chief Executive Officer at MarqMetrix. “We believed in Trico’s mission and are pleased to have developed this partnership for wireless products and services continually tracking key production assets, and watching for the slightest variation in normal operating conditions.

You can read the full release here: MarqMetrix Introduces Sensei™ Real-Time Lubrication Intelligence System with Trico Corporation.

Trico Introduces Sensei™ Real-Time Lubrication Intelligence System

For Immediate Release

Trico Introduces Sensei™ Real-Time Lubrication Intelligence System

New wireless monitoring technology can help manufacturers save time, maximize equipment uptime through data-driven maintenance

Pewaukee, WI, March 27, 2017 — Trico Corporation, a leading provider of lubrication management solutions, today introduced Sensei™, a real-time lubrication intelligence system.

Sensei, believed to be the first system of its type, wirelessly transmits oil level and ambient air temperature to a customizable, web-based dashboard. As a result, users gain real-time input on machine status and maintenance requirements. Sensei can:

- Reduce inspection time from hours to minutes per week.

- Reduce requirements for personnel to visit difficult- or dangerous-to-access areas.

- Help avoid downtime by providing alerts and warnings.

- Enable organizations to operate more efficiently by performing proactive, data-driven maintenance.

“The launch of Sensei represents a new ability to generate meaningful data faster and more efficiently than ever before. As a result, we are uniquely positioned to help customers develop cost-saving strategies and reduce the massive pressures of reliability,” says Jim Jung, President, Trico. “In combination with the services from the Trico Analysis Center, Sensei enables us to redefine lubrication management strategies for the Internet of Things era.”

Sensei Applications

The first wireless sensors available as part of the Sensei system are oil level sensors designed to accompany Trico’s line of 8-oz. Opto-Matic vented and closed constant level oilers. Pumps, motors, gearboxes, fans, blowers and other equipment use constant level oilers to maintain a consistent fluid level.

Industrial and manufacturing applications include those in machining, petrochemical, chemical processing, primary metals, pulp and paper, food and beverage, power generation, water management, mining and other industries. Maintenance managers, directors of operations, facility managers, lubrication technicians, millwrights and reliability engineers in these industries stand to gain valuable insights from Sensei’s real-time monitoring capability.

Results from Initial Installations

“Sensei has helped us rule out and identify problems,” says Mike Walton, ICML*, MLT-II, Mechanical Technician at Irving Tissue, St. John, New Brunswick. Irving Tissue tested Sensei on the Yankee Exhaust Fans that assist in the drying process. Walton notes that the reliability team at first thought one fan had an oil leak because it lost so much oil in a short period, but historical data provided by Sensei showed that there were periods as long as four to five months where oil level stayed constant.

“On fan 200-190-21, Sensei enabled us to rule out a leak and look for other causes,” says Walton. “Conversely, fan 100-190-53 leaked constantly. On closer examination, we found it had a leaking fitting going to the bearing housing, as well as a bad seal. Work orders were entered to correct those problems.”

*International Council for Machinery Lubrication, Level II Machinery Lubrication Technician

Inside the System

The Sensei system includes three components:

- An oil sensor that measures the oil level, oil consumption and ambient temperature.

- The Sensei gateway (a router) that securely receives data and transmits it to the cloud. The gateway handles up to 64 sensors at a radius of 250 feet. Repeaters expand the network as needed.

- An intuitive, web-based dashboard for real-time intelligence (there is no need to install software). The dashboard is customizable with displays for oil level by device, daily alerts and several other functions.

“Due to competitive pressure, cost-saving requirements and retiring skilled trade talent, many companies no longer have in-house capabilities. That’s where Trico and our 100 years of lubrication expertise come in, helping customers turn data into action,” says Jung. “By pairing data from Sensei with our industry-leading oil lab services and analysis, Trico provides an unmatched ability to protect and extend the life of critical equipment.”

Custom Developed

To create Sensei’s customized optical sensor pack that captures oil levels, Trico partnered with MarqMetrix, a Seattle-based company that also helped develop the wireless network solution that flows data into the Sensei cloud platform.

“Using patented technology, we can automate previously manual and labor intensive measurement processes. Sensei technology has limitless opportunities for industrial and manufacturing applications,” says Brian Marquardt, CEO of MarqMetrix.

How to Get Sensei

To help ensure maximum impact with the expert monitoring made possible by Sensei, the system is only available through a select network of trained distribution partners, or directly through Trico. Companies can request access to a simulated Sensei dashboard that illustrates available information and configurability,.

Sensei oil level sensors are available as a complete oiler, but can be retrofit to existing Trico Opto-Matic installations by replacing the upper bulb assembly. It is not compatible with competitive oilers.

About Trico

Trico Corporation is a total lubrication management service and products company that focuses on increasing industrial asset performance and reliability. The company offers assessments for lubrication management programs, equipment audits, oil analysis, training, and a complete line of high-performance lubrication products. Founded in 1917, Trico’s mission is to protect and extend the life of critical equipment, providing customers with peace of mind through machines that run more productively. Principal offices are in Pewaukee, Wis., and Cleveland, Ohio. For more information, visit tricocorp.com or call (800) 558-7008, ext. 117.

Trico Contact: Editorial Contact:

Jim Jung, President Dennis Estenson

Trico Corp (262) 544-8800

(262) 691-9336 dennis@rocketlawnchair.com

jjung@tricocorp.com

Bringing Raman Spectroscopy to the Undergraduate Laboratory

Designed specifically for the educational environment, a Raman tool incorporates a safe way to operate laser in a durable, open package, offered at about a third of the price of a traditional Raman spectrometer. All of the components of a Raman spectroscopy system are integrated into a complete teaching platform.

Spherical Lens Probes Open New Possibilities in Raman Spectroscopy

Since its inception in 1928, Raman spectroscopy has allowed scientists to see a chemical “fingerprint” of material. Using light, substances are identified by the way specific wavelengths interface with a sample and are scattered. Pioneered by Sir C.V. Raman 90 years ago using simple sunlight with a series of filters to read a sample, Raman spectroscopy has evolved to become an information-rich measurement technique.

![AnalyticalSci-SciX2020-banner-300x250[2864] MarqMetrix at SciX 2020](https://marqmetrix.com/wp-content/uploads/2020/09/AnalyticalSci-SciX2020-banner-300x2502864-1.png)