By Brian Marquardt, Ph.D, MarqMetrix Founder & CEO. Published in the April 2021 issue of Pharmaceutical Technology.

Demanding regulations and tight quality tolerances drive the need for accurate analytical information in real-time to ensure manufactured drugs are safe and effective. Process analytical technology (PAT) must deliver fast and data-rich analysis so that manufacturers can accurately measure critical process parameters (CPPs) that affect critical quality attributes (CQAs). PAT is crucial to the process of manufacturing drugs in compliance with regulations.

PAT uses established spectroscopy technology and advanced statistical computer modeling to deliver information about the manufacturing process. Optimal system characteristics include fast, easy access to analytical data to address production problems with minimal downtime; a nondestructive process so drug product is not wasted in quality testing; reliability; and low maintenance.

Raman spectroscopy measures the light-matter interactions (the scattering of photons due to bond vibrations in a molecule) via a laser and detector. The vibrations generate a Raman spectrum, a unique molecular fingerprint of the analyzed substance, providing both quantitative and qualitative molecular compositional information. The chemometric models produced by a Raman system by collecting and preprocessing molecular compositional data are linear and repeatable.

Raman technology has been used in pharmaceutical manufacturing for more than 10 years to analyze solids, powders, liquids, gels, gasses, and heterogeneous samples, and is recognized as in-line PAT tool to measure CPPs.

Because Raman systems use a laser to excite the molecules, measurement times range from milliseconds to seconds and do not require sample prep steps or separations. Hardware advances have improved reliability, ease of use, data quality, signal strength, communications, and the ability to interface with multivariate analysis software packages.

Raman for pharma: PAT sensor implementation

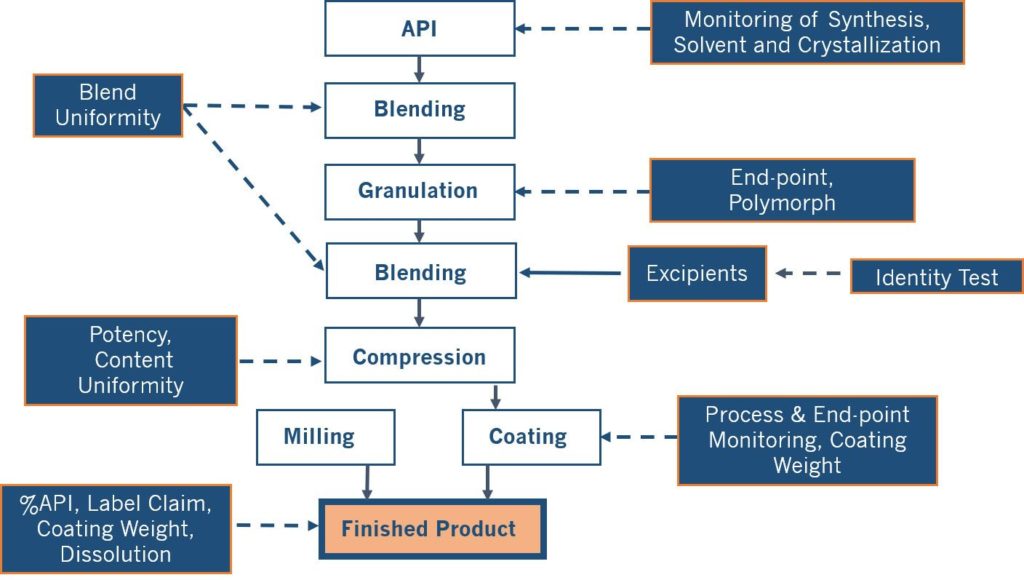

PAT is recognized as an important tool for monitoring pharmaceutical manufacturing processes, and Raman spectroscopy has emerged as a fast, effective, and versatile PAT real-time analyzer for multiple stages of the manufacturing process. Figure 1 illustrates the typical unit operations in pharmaceutical manufacturing.

Figure 1. Raman PAT sensor implementation

Raman spectroscopy has been applied as a multidimensional PAT sensor for real-time monitoring of CQAs and real-time release of products. Further, Raman spectroscopy has been used in continuous secondary manufacturing and small-volume continuous manufacturing of APIs.

Raw material identification/verification

Raman spectroscopy provides a molecular fingerprint of incoming excipients and APIs. As a result, Raman is used by many major pharmaceutical companies for verification and identification. Two critical Raman attributes that support verification and identification are specificity and sensitivity. Raman can identify different polymorphic forms where significant differences are seen in the collected Raman spectrum’s low-frequency region. Raman also identifies material adulterations, whether accidental or intentional.

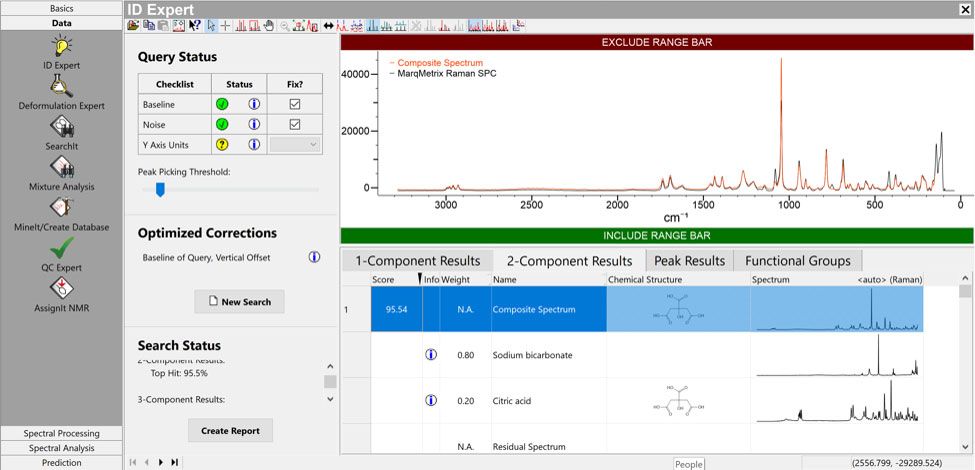

In Figure 2, the Raman component results of Eno, an over-the-counter antacid composed of sodium carbonate, sodium bicarbonate, and citric acid, are shown.

Figure 2. Eno acid reflux product mixture analysis: Positive ID using KnowItAll Spectroscopy Edition software (Wiley Science).

Measurements for analysis are made either by direct contact using a handheld fiberoptic probe or a contactless probe, which analyzes a sample through a glass or plastic container. Once the Raman spectrum is collected, it is compared to a commercially available or custom-built library. The output is a simple indication of pass/fail. If the material passes the identification/verification stage, it can be released into the system. If the material fails, a sample is taken for further laboratory analysis, and that lot could ultimately be rejected.

Blend uniformity with Raman

On-line analysis of blend uniformity by Raman spectroscopy provides more benefits than traditional sample extraction (thief sampling) and off-line analysis. On-line Raman spectroscopy obtains a large number of spectra, which generates data-rich blend profiles during the blending process, with spectral collection rates collected in approximately two seconds.

A small solid-state Raman spectrometer connected to a fiberoptic probe can be installed on various blending systems such as V-blenders or intermediate bulk containers (IBC). For IBC implementation, the spectrometer must rotate with the IBC, so the instrument must be small, battery-operated, and able to transmit spectra in real-time wirelessly to a remote computer.

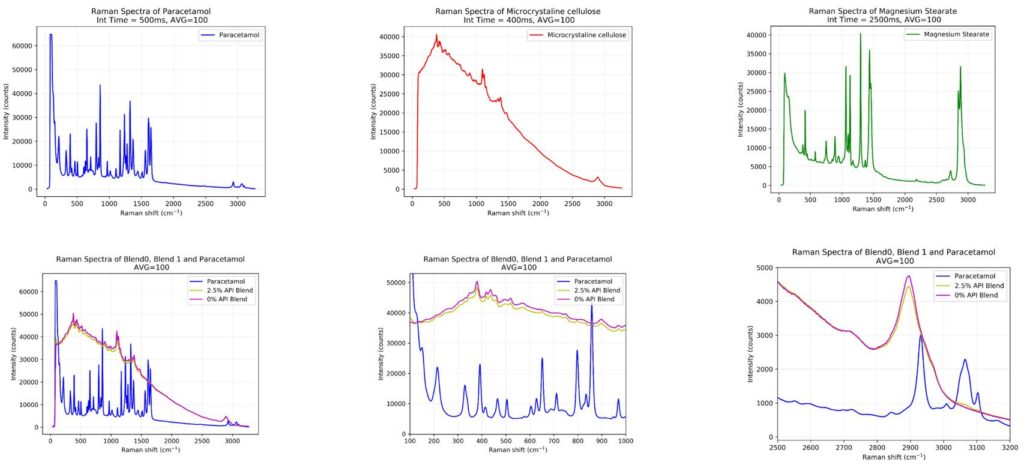

A model-free statistical approach monitors the blend uniformity by calculating a spectral region’s moving block standard deviation specific to the API (Figure 3). Once the standard deviation reaches the threshold required for a period of time, the blend is deemed uniform and is stopped, and the batch is released. This use of real-time Raman spectroscopy can reduce batch cycle times and ensure product quality and consistency.

Figure 3. Monitoring paracetamol, microcrystalline cellulose (MCC) and magnesium stearate (MgSt) with Raman spectroscopy.

In-situ tablet feed frame measurements %API

In the manufacture of pharmaceutical tablets, Raman spectroscopic methods can provide a real-time, nondestructive measurement of the API concentration to ensure product quality and uniformity and enable real-time release of a batch.

A port on the feed frame or a sapphire window allows either contact or contactless material measurement by Raman spectrometers before tablet compression. The Raman probe is a crucial component in obtaining high-quality spectra.

For the contact measurement, the focusing of the Raman excitation beam or probe cleaning is not necessary if using a touch probe design that is self-cleaning in a moving powder stream.

A contact-free interface can be used to measure through a sapphire window; a standoff distance of approximately 10 mm will ensure that the sapphire window has little or no influence on the Raman spectra.

In conventional batch analysis, operators collect the required number of tablet cores throughout a batch, based upon the standard operating procedure for sampling each batch. The sample set is sent for a high performance liquid chromatography analysis on each tablet, a process that can result in a batch being held for several hours, if not an entire day.

By using Raman spectroscopy, each tablet core is analyzed using a contactless probe and closed tablet holder, generating analysis results in seconds. With this method, the entire sample set can be analyzed in less than one hour before releasing the batch.

In proprietary tests, Raman spectroscopy has been shown to lower the limit-of-detection due to excellent specificity and sensitivity when compared to other spectroscopic technology, particularly for formulations with low API loads.

Coating thickness (weight)

Tablet film coating is a standard pharmaceutical process in which various coating formulations are applied to tablet cores. To ensure the product’s efficacy and safety, along with the desired dissolution profile, consistent quality of the coating is required. A CQA of the film coating is the film thickness, which can be monitored in real-time by Raman spectroscopy.

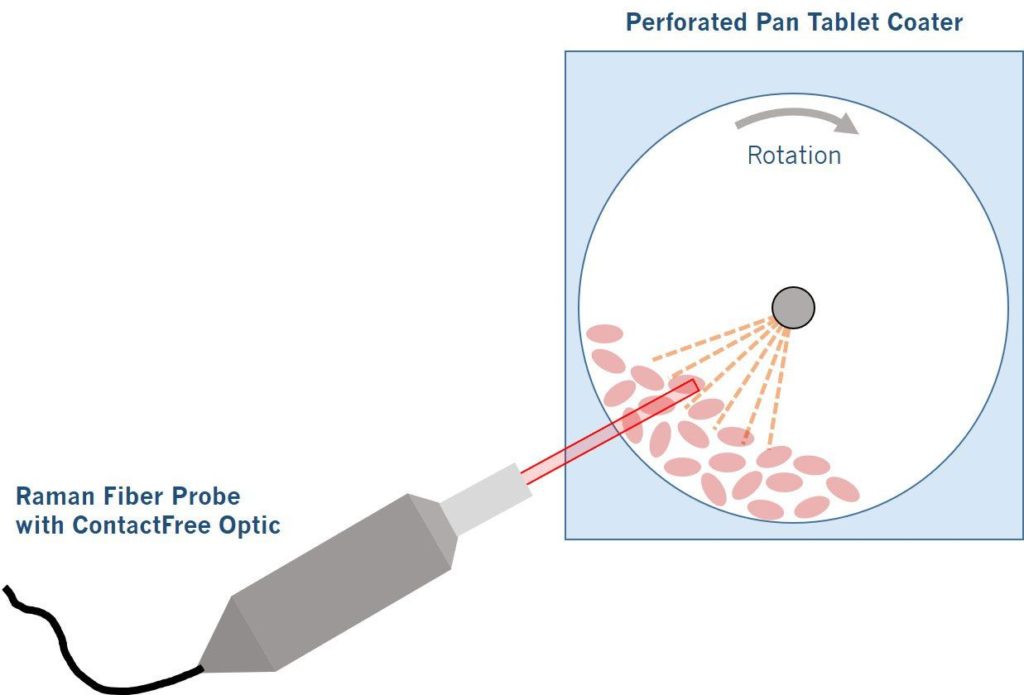

In unpublished customer application data, a high-volume, contactless probe with a beam diameter of 3.5 mm and a standoff distance of 100 mm has been used to measure film thickness on a perforated drum coating machine (Figure 4). Raman spectra are collected every few seconds and analyzed using a multivariate data analysis (MVDA) model.

Figure 4. Rotating perforated pan tablet coater with contact-free Raman fiber optic probe.

Real-time coating thickness results can be verified visually and sent to a control system via industry-standard protocols such as OPC UA (Unified Architecture) or DA (Data Access), Modbus, Profibus, or 4-20mA outputs. The control system optimizes the process by adjusting the coating spray rate or drum speed to ensure that the final product meets the coating thickness specification. This step will ensure that no out-of-specification tablets are produced while improving the process efficiency by potentially reducing the batch coating time and ancillary testing.

Conclusion

Pharmaceutical manufacturers understand the value multidimensional PAT technology offers in ensuring continued high-paced operations. As a PAT sensor, Raman can deliver accurate and data-rich compositional analysis in approximately two seconds—depending on the application—in a nondestructive process minimal sample preparation.

Accessible and portable Raman systems can be used throughout the pharmaceutical manufacturing process from mixing to blending. Matching the appropriate system to the pharmaceutical process is key to maximizing the capabilities of Raman technology.

About the author

Brian Marquardt, PhD, is founder and CEO of MarqMetrix, Inc., and director of the Center for Process Analysis and Control (CPAC) at the University of Washington.

Follow us on social media: