REFINED MEASUREMENT FOR THE OIL & GAS INDUSTRY

POINT-OF-PRODUCTION QUALITY MEASUREMENT LIKE NEVER BEFORE

Accurate measurement is nowhere more essential than in the petroleum and chemical industries. Understanding the chemical composition of raw materials and the consistency of processed products can create an immense competitive advantage at every point in the process.

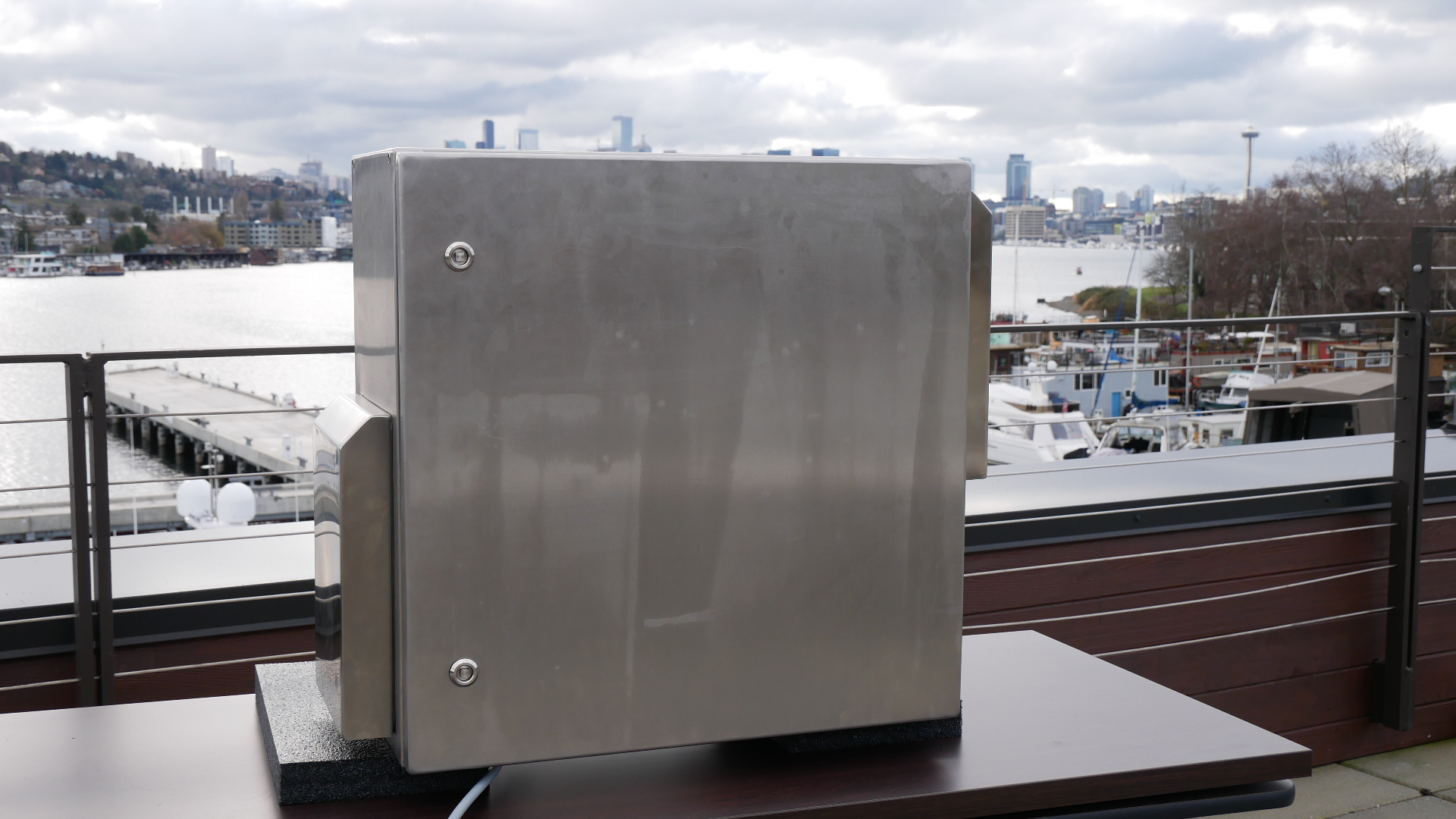

MarqMetrix® TouchRaman® BallProbe® end optics have been successfully deployed to assess composition during exploration, characterize crude and distillates, determine the composition of natural gas, and perform environmental assessments. MarqMetrix process Raman analyzers and BallProbes are the perfect tools for online process characterization, quality measurement, and control.

The MarqMetrix BallProbe is available in Hastelloy C-276, a nickel molybdenum-chromium superalloy able to withstand the extreme physical and chemical environments found in the O&G industry.

The Raman BallProbe’s spherical sapphire lens can effectively withstand direct contact with the sample, even in hot (300°C), high pressure (> 400 bar), and harsh corrosive conditions. MarqMetrix has demonstrated proficiency in adapting these probes to a wide array of applications in the O&G industry providing robust, reliable compositional measurements for process analysis and control.

Resources

WEBINAR

Raman and GC: Enhancing Analytical Methods

WEBINAR

Raman Natural Gas Field Analysis: C1-C6+, CO2, H2 and N2

BLOG

Identifying Gasoline Fuel Properties with Raman

APP NOTE

Enabling Natural Gas Field Analysis for Certification and QA with Raman

APP NOTE

Why the Downstream Segment Should Count Raman as a Data-Rich Complement to Existing Analytical Technology

BROCHURE

Raman for Downstream Applications

WHITE PAPER

Accelerating Refined Fuel Analysis with Raman

ARTICLE

Raman Spectroscopy: Reducing the Time to Verify Gasoline Blends