INDUSTRIAL FERMENTATION: MEASURING THE FUTURE

DISCOVERING NEW SOLUTIONS WITH RAMAN

Industrial fermentation is a growing industry creating innovative solutions to the planet’s greatest environmental challenges. The sustainable production of chemicals from bio-based raw materials such as corn, sugar, and starch require a sensitive real-time measurement solution for the fermentation process. Raman spectroscopy offers real-time analysis with process control and as a proven solution for the biopharma industry, the capabilities are immediately applicable to industrial fermentation applications.

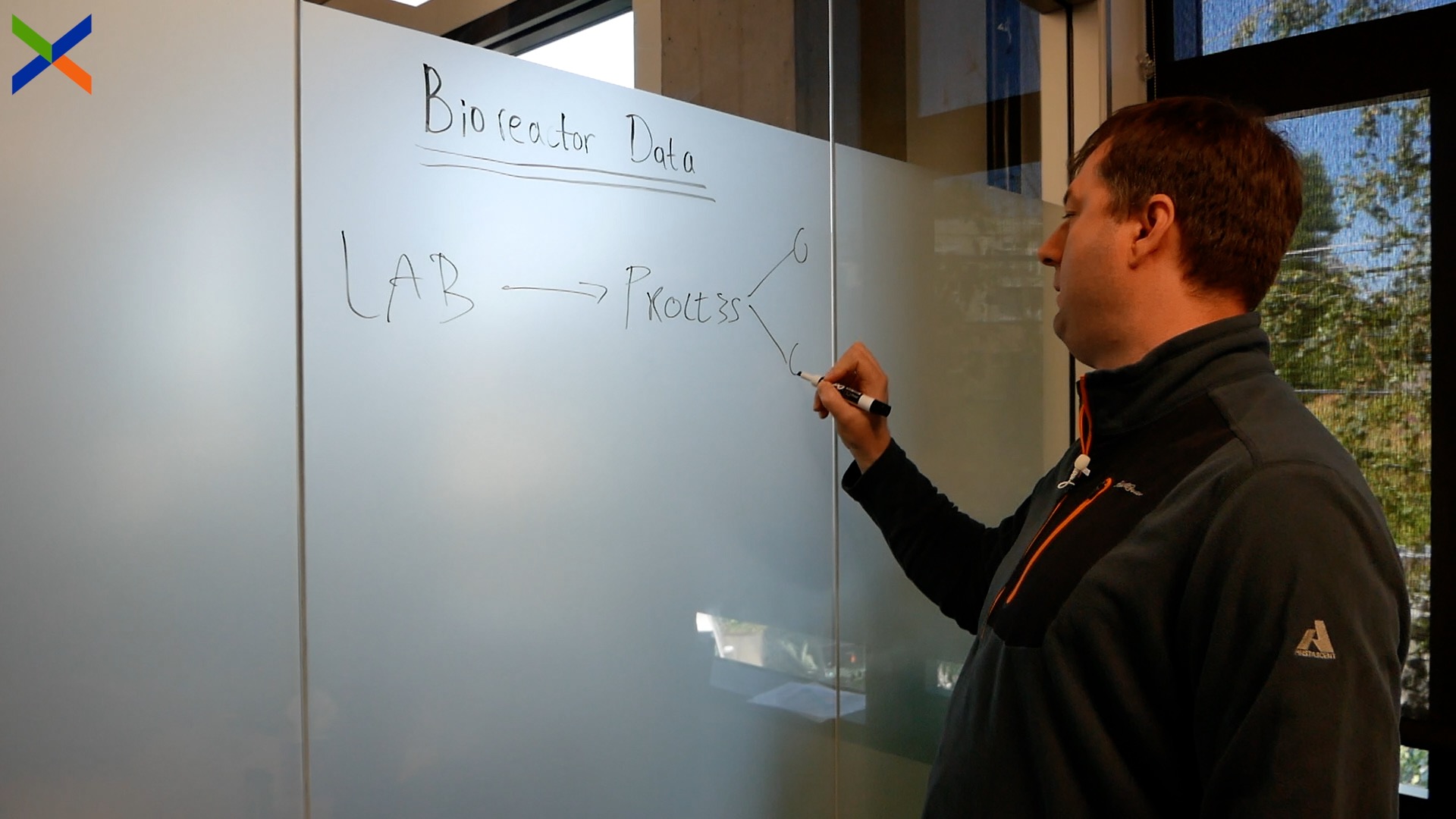

CREATING NEW MATERIALS WITH INDUSTRIAL FERMENTATION & RAMAN

Industrial fermentation companies are transforming the carbon dioxide captured during industrial processes into everyday products such as fuel, chemicals, and rubber.

For this to work, the fermentation process must be closely monitored to realize the desired yield and to control product quality. Raman offers real-time analysis of the feed stream, of the analytes (nutrients), byproducts and products.

Applications

- Optimize carbon capture – carbon monoxide to acetic acid & ethanol

- Transform sugar cane to ethanol

- Convert hydrocarbon feedstocks into high volume chemical building blocks

INDUSTRIAL FERMENTATION IS HELPING TO SOLVE THE WORLD’S FOOD SHORTAGE

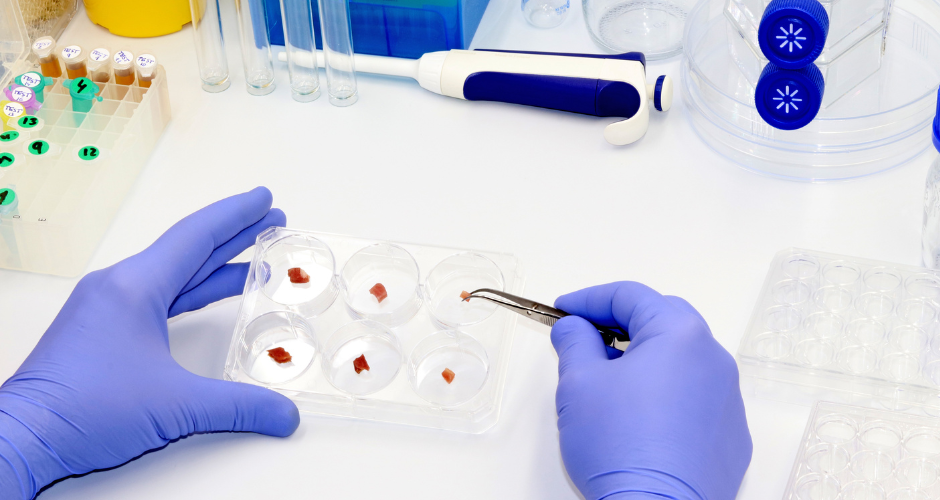

About 40% of greenhouse gases come from agriculture. Beef production drives climate change through cows emitting methane and by deforesting in favor of grazing land. Cultivated meat producers are decreasing the need to raise and farm animals for food by using industrial fermentation to grow animal cells in bioreactors.

Raman allows cultivated meat producers to monitor high cell densities and yield. The immediate response, nondestructive sampling and structural information Raman provides makes it a go-to tool for development, optimization and process control.

Applications

- Monitor proteins and alcohols

- Optimize food ingredients

- Analyze fragrances and sweeteners

The MarqMetrix All-In-One, a solid-state Raman system, has a small footprint and industry standard connections to bioreactors. Analyzer performance stability ensures seamless deployment to multiple bioreactors, now or in the future.

The All-In-One offers:

- Raw material screening for media components

- Real-time fermentation monitoring for consumption of starting material and product formation

- Non-destructive results and scalability