Gasoline fuel properties such as API, benzene, RON and MON must be measured accurately and precisely to enable refineries to expedite quality assurance and bring gasoline to market quickly. To do this, refinery labs must analyze many hundred samples of gasoline per day. In a medium size refinery, this can be 250 per day – in a large refinery, the number can be as high as 500 per day. Throughput is a main challenge for these labs as the speed samples can be processed is dictated by the lab’s measurement technology.

How are Gasoline Fuel Properties Identified?

The analytical tools conventionally used by the Oil & Gas industry to identify gasoline fuel properties are gas chromatographs, simulated distillation, flash & freeze point devices, densitometers, vapor pressure testers, knock test engines for RON & MON and many others. Another method, solid-state Raman spectroscopy, can measure multiple properties of gasoline accurately, precisely, and rapidly – in a matter of seconds.

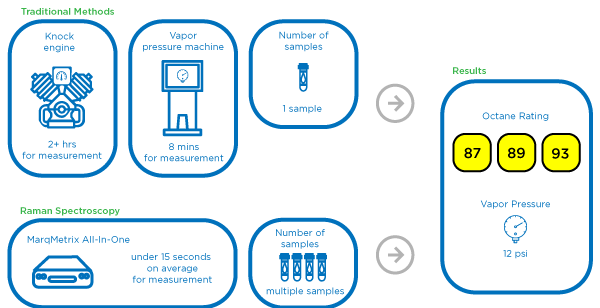

Measuring octane numbers, a key metric for the release of gasoline into the marketplace, is a good example of how Raman can accelerate critical refinery applications when compared to traditional methods. For example, Raman spectroscopy can analyze 180 samples in the time it takes knock engines to analyze a single sample. Raman is also flexible – labs can run multiple analysis methods simultaneously.

Modeling Gasoline Fuel Properties

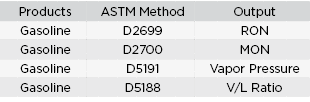

In a recent experiment conducted by MarqMetrix, 87 gasoline samples were analyzed with ten scans per sample. The total analysis time was five seconds per sample. The generated spectra were processed using SOLO (Eigenvector). Models were built using either Partial Least Squares (PLS) or Partial Least Squares Discriminant Analysis (PLSDA). Cross validation was used to optimized model calibration. For the gasoline models, a holdout set was retained to determine model accuracy. The reference data used to build the model was collected using the relevant ASTM method.

*D5191 is an automated mini test method for the automated determination of Dry Vapor Pressure Equivalent (DVPE) often called Reid Vapor Pressure (RVP)

The 87 gasoline samples were used to build models to predict six fuel properties for gasoline. The table below outlines the properties measured and the resulting model accuracy.

The use of Raman spectroscopy in a refinery can significantly increase throughput, reduce overhead, and improve the safety environment of a laboratory. In addition, the transferability of the Raman methods allows models to be built in a lab and applied to process instruments in the field, increasing the return on investment and propagating process analytical technology.

Refinery Applications

MarqMetrix’s core models offering allows refineries to:

• Certify gasoline blends

• Analyze Naphtha pretreats

• Identify sulfur peaks

• Analyze CO, CO2 and oxygen level concentrations

• Simulate distillation

Want to learn how to identify diesel and jet fuel properties with Raman? Read our white paper >