Advances in measurement technology for the oil and gas industry, such as Raman spectroscopy, have opened new doors for quality assurance and process control at a fraction of the cost. Some of Raman’s biggest advantages are calibration stability and the elimination of required maintenance, both of which alleviate many of the headaches presented by traditional measurement methods. Gas chromatography (GC) has long been a standard for oil and gas monitoring. However, gas chromatographs can be less reliable, requiring more maintenance than other analytical technologies. The total cost of ownership of a gas chromatograph can be up to $1 million over a 10-year lifetime. Included in that price tag is the cost of consumables, such as carrier gases, calibration gas, fittings, detectors, and columns. On top of those costs, you must account for the cost of an experienced analyzer technician to keep the GC running within specification.

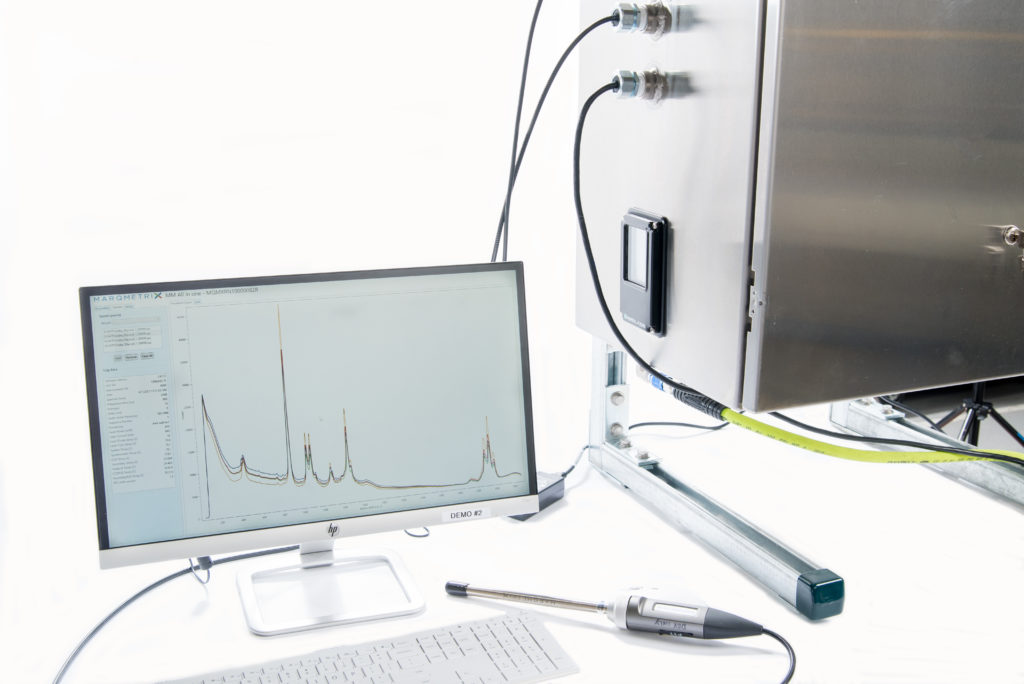

A process Raman system eliminates these ancillary costs while offering reliable process analysis. Raman hardware has come a long way in terms of cost, size and stability. However, unique safety considerations are required to operate any analyzer in a process setting, especially in the oil and gas industry. This article covers the advantages of using a hazardous location certified enclosure to perform process measurements quickly, safely and effectively with a MarqMetrix All-In-One Raman system.

Unlocking Real-time Oil and Gas Monitoring at the Point of Need

Thanks to its high-speed data acquisition and remote sampling capability, the All-In-One provides analytical information faster than comparable technologies, such as a GC. Additionally, MarqMetrix manufactures numerous process-capable sample interfaces to allow for immersion into a reactor or process stream or integration into an existing flow path with a FlowCell™, removing the risk of handling toxic samples and simplifying the sampling process.

Modern Raman systems are not only high-performance but also stable and safe. Solid-state construction, a core All-In-One feature, enables mobility, stability, and adaptability. Raman systems are now capable and suitable for non-lab settings and application in many hazardous processes.

But how do you safely take a Raman analyzer to the point of need in the oil and gas industry? A hazardous location certified enclosure for your Raman equipment is the best way to assure safety and regulatory compliance while protecting workers and the integrity of your product.

Make Sure your Enclosure Meets Purge & Pressurization Requirements

A Class I Division 2 certification, or other similar hazardous enclosure ratings, require that there is no risk of a spark, flame, or high heat in the presence of flammable gas or vapor. Fortunately, purge and pressurization systems are available and designed to expel any potentially hazardous air, replace it with inert gas, and over-pressurize the enclosure to ensure no hazardous gas ingress occurs. MarqMetrix hazardous location rated enclosures come equipped with an integrated temperature control system that allows for custom internal pressure and temperature control for any temperature range.

Look for Easy System Setup & Sampling

Protecting your Raman system in a Class I Division 2 enclosure should not impact setup and use. Ideally, the enclosure will come pre-wired and customized with all the necessary connections you require for your installation. The enclosure should also integrate easily into your application. MarqMetrix hazardous location certified enclosures make use of Unistrut mounting hardware for easy placement at the point of measurement.

Easy install and hazardous location certifications are just part of the equation for using process Raman for oil and gas monitoring. You also need a system that makes data acquisition easy and repeatable. One of the best ways to ensure consistent data is to use a sampling interface that requires no sample preparation and integrates easily into your production process. MarqMetrix AIO process Raman systems are optimized for use with our wide array of standard probes. The BallProbe® line allows for easy immersion in liquids or solutions, as well as the ability to sample solids, pastes, gels, and powders. For use with a flowing sample, the FlowCell™ offers seamless integration and in-line sampling capability. We also provide custom probes and interfaces for customers with unique sampling needs. Whether it is high pressures, high temperatures, or situations that require special alloys or custom mounting options, MarqMetrix can make an interface suitable for your needs.

Placing one or more of our AIO systems in a hazardous location enclosure can provide many tangible benefits. Ultimately, an enclosure allows you to place your Raman system at the point of need with peace of mind. For more information, please contact us.

https://youtu.be/HMOWyDeC1kw