Atline Raman spectroscopy involves collecting Raman spectra of samples at a location near the production process but not directly in the process stream. This offers a flexible and efficient real-time analysis and decision-making method while minimizing the need for extensive sample preparation and complex measurement setups.

Atline analysis allows for the potential for more detailed and accurate analysis than online or inline analysis, but the results are not immediately available. Atline Raman spectroscopy can be used to analyze samples from a production process, to identify the composition of unknown materials, or to determine the purity of a sample. It is often used for quality control in the food and beverage industry.

Common Uses and Applications for Atline Raman spectroscopy

- Quality control and process monitoring: Atline Raman spectroscopy is widely used in industries such as the pharmaceutical, chemical, and food and beverage to monitor and control the quality of products and optimize manufacturing processes. It allows for near real-time analysis of raw materials, intermediates, and finished products, helping to ensure consistency and identify any deviations or impurities.

- Raw material identification: The atline Raman spectroscopy method can be used to quickly identify and verify raw materials used in manufacturing processes. It provides a rapid and non-destructive method for material characterization, allowing for faster material screening and reducing the risk of using incorrect or substandard materials.

- Blend uniformity analysis: In industries where blending or mixing of different components is critical, atline Raman spectroscopy can be used to assess the uniformity of the blends. By analyzing the Raman spectra of samples taken at different locations within a blend, it is possible to detect inconsistencies or inhomogeneities in the mixture.

- Process optimization and troubleshooting: When near real-time monitoring of process parameters and chemical reactions is critical, atline analysis can play a crucial role. By analyzing the Raman spectra, it is possible to understand the changes occurring during the process and adjust or troubleshoot any issues that may arise.

- Contamination detection: another common application in troubleshooting and optimization is identifying contaminants or foreign particles within a sample. Atline Raman spectroscopy can be used to quickly determine the presence of impurities, contaminants, or unexpected components, allowing for immediate corrective actions to be taken.

- Research and development: Atline Raman spectroscopy is utilized in R&D settings for material characterization, formulation development, and studying reaction kinetics. It provides valuable insights into molecular structures, polymorphs, and chemical interactions, aiding in the development of new products and processes.

Final Thoughts

There are four distinct methods of Raman data collection: inline, online, atline, and offline analysis, each carrying its own set of advantages and disadvantages. Depending on the application and experimental setup, Raman spectroscopy can be effectively combined with any of these methods to identify and characterize the chemical and physical properties of materials using diverse approaches.

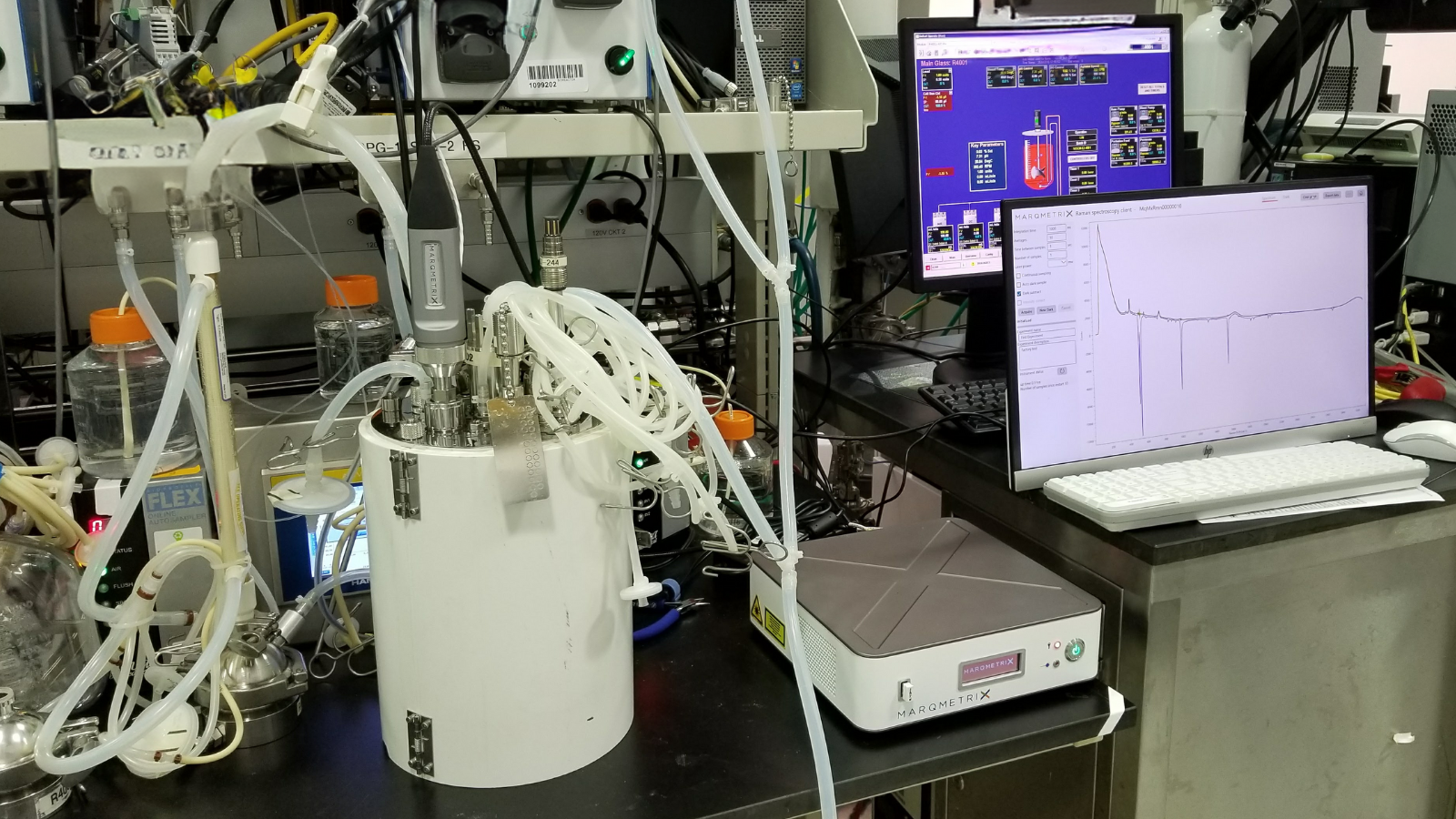

Whether you require measurements at any stage of your process, MarqMetrix offers a comprehensive Raman system and sampling interface to enhance your compositional measurements. With advanced solid-state technology, our Raman systems provide unmatched flexibility in placement, interface, and sample type while ensuring top-notch performance. To achieve optimal results, it is crucial to select the appropriate sampling interface for your specific applications. If you need assistance in choosing the ideal Raman system for your requirements, our team of experts is readily available to assist you. Simply click here to get in touch with us.