Inline, online, atline, and offline analysis are four different methods of data analysis, each with its own advantages and disadvantages. Depending on the application and experimental setup, Raman spectroscopy can be used in conjunction with each method to identify and characterize the chemical and physical properties of materials in different ways. Here are the differences and example uses for each:

Inline Analysis

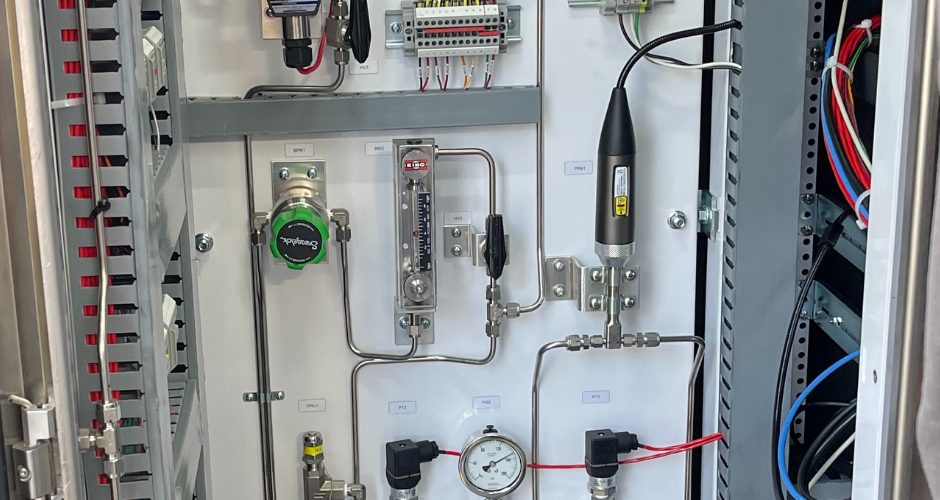

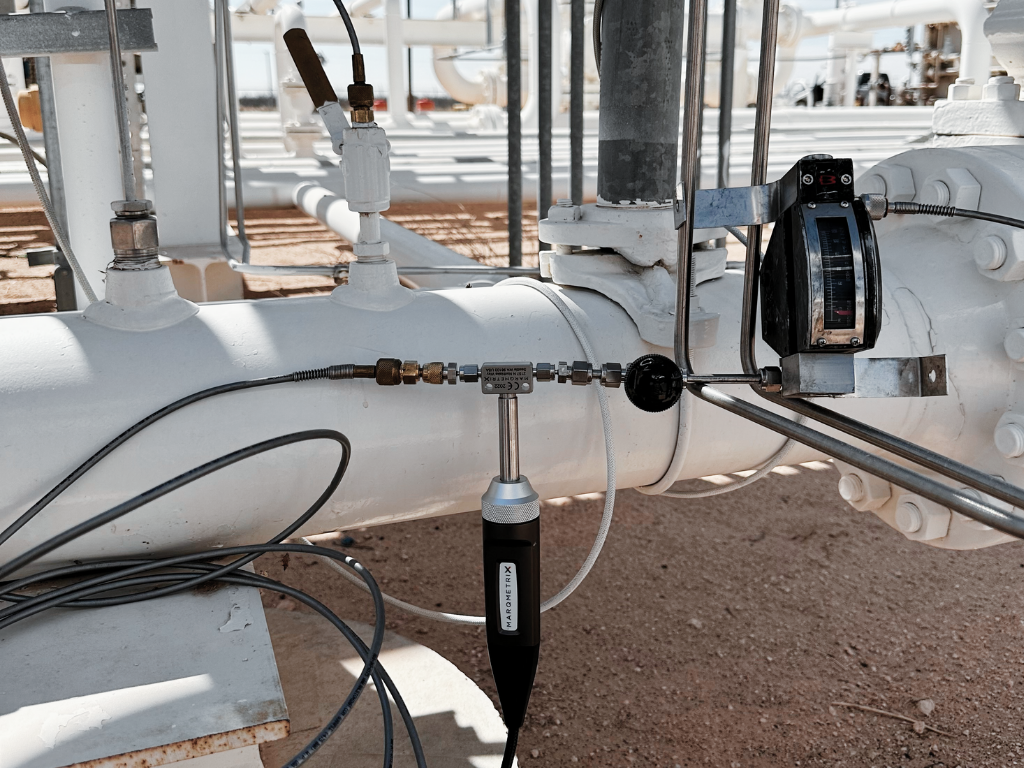

In this type of analysis, a solid-state Raman spectrometer, such as the MarqMetrix All-In-One, is integrated directly into the manufacturing or processing line, allowing for real-time monitoring and control of the process. This approach involves continuously monitoring the Raman signal during a chemical reaction or manufacturing process. The Raman probe is integrated into the process stream, allowing real-time monitoring and control of the reaction. Real-time monitoring allows for immediate corrective action to be taken, reducing waste and improving product quality. This approach is useful for studying the kinetics of a reaction or optimizing the reaction conditions.

Example uses: Inline Raman spectroscopy is used in the pharmaceutical and chemical industries to monitor the composition and concentration of chemicals in a production line, to track the progress of a chemical reaction, or to ensure the consistency of the product during manufacturing.

Online Analysis

Online Raman spectroscopy is similar to inline analysis, but it is typically performed in a separate area adjacent to the production line. The samples are transported from the production line to the Raman spectrometer through a sampling interface.

This approach involves periodically sampling the reaction mixture and analyzing it using Raman spectroscopy. The sampling is done automatically, and the analysis can be performed in a matter of minutes. This approach is useful for quality control and batch-to-batch consistency in manufacturing processes.

Example uses: Online Raman spectroscopy can be used for rapid analysis of incoming raw materials, to monitor the quality of a product in real-time, or to identify contaminants in a process stream. It’s extremely useful in monitoring the quality of polymers and other materials during production.

Atline Analysis

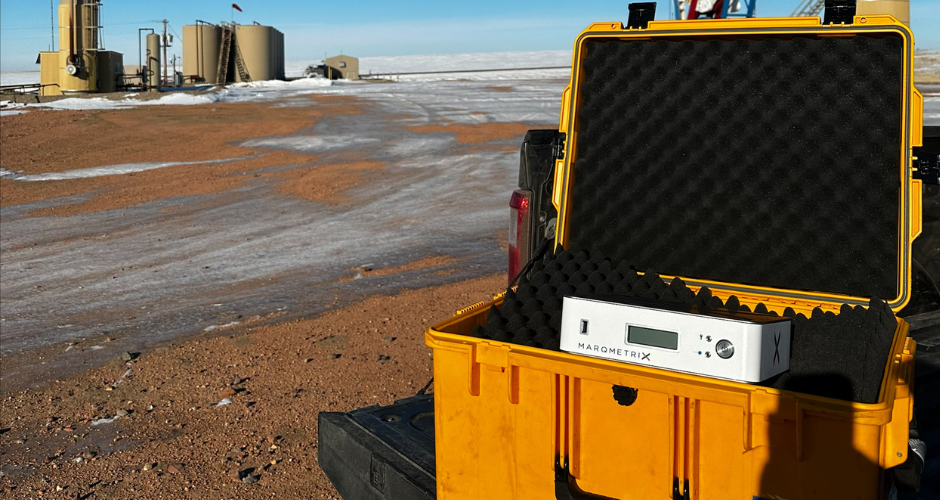

Atline analysis allows for more detailed and accurate analysis than online or inline analysis, but the results are not immediately available. In this type of analysis, samples are taken from the process stream manually and brought to a mobile Raman spectrometer for analysis. This approach provides more detailed information about the reaction products and can be used to identify impurities or contaminants.

Example uses: Atline Raman spectroscopy can be used to analyze samples from a production process, to identify the composition of unknown materials, or to determine the purity of a sample. It’s often used for quality control in the food and beverage industry.

Offline Analysis

Offline Raman spectroscopy is similar to atline analysis, but it is performed in a laboratory setting. A key difference is that offline analysis is sometimes performed hours or even days after the sample was collected. This approach is useful for forensic analysis or for studying samples that cannot be easily analyzed in real time. This type of analysis is the most accurate and precise, but it is also the most time-consuming and costly.

Example uses: Offline Raman spectroscopy can be used for detailed chemical analysis of samples of rocks and minerals, to determine the structure and composition of materials, or to perform advanced research on new materials and compounds.

In summary, each type of Raman spectroscopy analysis has its own advantages and limitations, and the choice of analysis depends on the specific application and requirements of the experiment or process. Knowing how each type of analysis works in different applications can help you determine which is the best fit. Selecting the appropriate Raman equipment can also play a major role in the success of your analysis.

Measurement Anywhere, Anytime

No matter where you decide to perform measurements in your process, MarqMetrix has a Raman system and sampling interface that will improve your compositional measurements. Modern, solid-state Raman systems allow for flexibility in placement, interface, and sample type without sacrificing performance. For the best results and performance, it is imperative to choose the correct sampling interface for each of your applications. If you need help determining the best Raman system for your application, reach out to one of our experts by clicking here.