Biopharmaceutical production requires a near-constant stream of compositional information to run efficiently. Solid-state process Raman is a proven technology for collecting that information while greatly reducing maintenance and operating costs compared to traditional physical sampling-based measurements. While the composition measurements are valuable to understand a bioprocess the end goal is to use this information for optimization and control. To realize this goal the compositional information can be processed using data science tools and packages that develop robust predictive models for key processes. Once these models have been developed and validated they can then be easily deployed to multiple Raman systems. Deploying the predictive models will provide actionable information, indicating when feeds or controls should be activated to optimize the bioprocess. This article will break down the simple process of building and applying quantitative Raman solutions to demonstrate how easy it is to add value with an All-In-One Raman system.

Creating a Model for Glucose

In biopharmaceutical production, cells require a feeding cycle of glucose to enable cell reproduction. Our Raman solution leverages our AIO hardware and data science tools to model the glucose content of a bioprocess and tell you exactly when to add more glucose to ensure cell production at a precise rate.

Global Data for a Global Solution

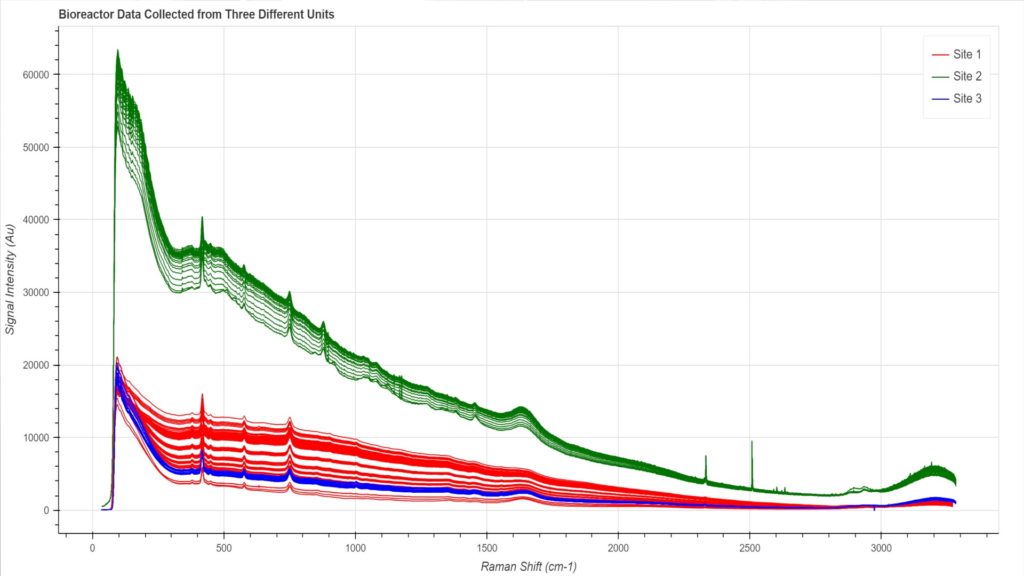

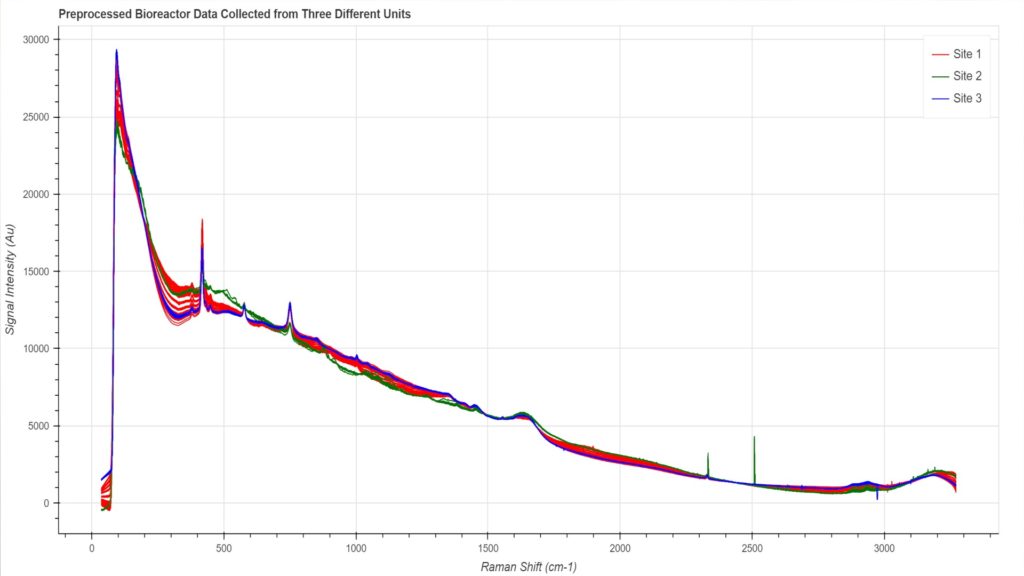

Building this model begins with the process of collecting data. Fortunately, we had three customers already using MarqMetrix AIOs to measure glucose concentration (and other analytes) who shared their data sets with us. Even though these three data sets were collected from different processes, with different instruments, using variable measurement parameters from locations around the globe, we were still able to build a strong predictive glucose model. While the combined data looked quite messy at first, we were easily able to clean up the data and make all the information work well together. This was a relatively simple task due to the stability of the AIO Raman system, and the data science tools at our disposal. Once cleaned (pretreated), the data were combined and processed to build our “global” glucose model.

The Power of Preprocessing

The ease by which we can preprocess data comes largely from three key qualities of the AIO Raman system, its stability, reproducible sampling interface, and factory calibration. These qualities ensure that every Raman system is extremely stable, accurate, and consistent with other AIO systems no matter the location. From this foundation, we can leverage fundamental preprocessing methods that target and amplify the relevant signals within the Raman information. The result was a predictive model that delivers greater precision and accuracy across multiple AIO systems. If you would like to learn more about the process of building a quantitative model using our Raman systems, check out this video:

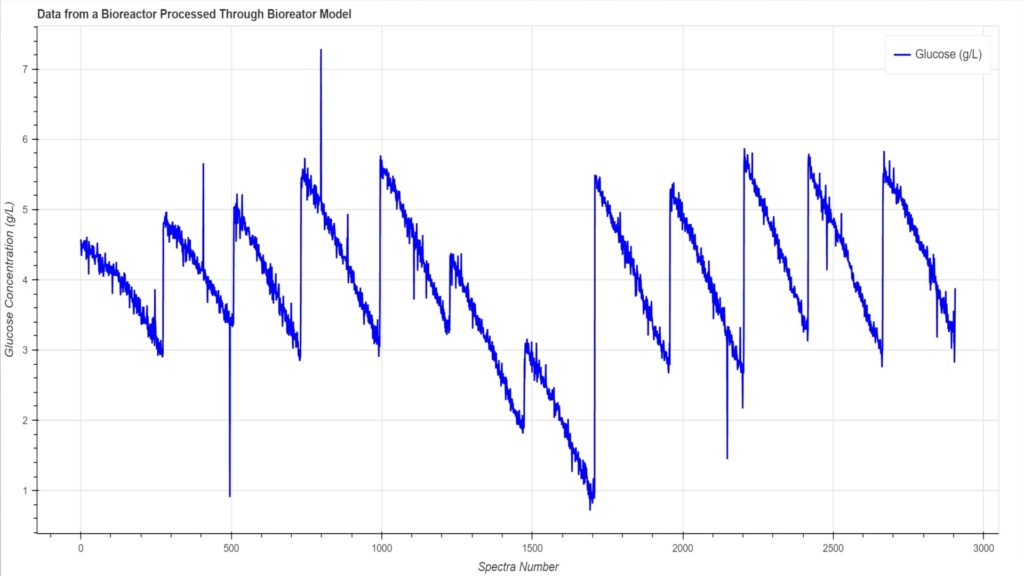

Knowing when to feed your Bioprocess with Data Science

After the predictive model has been made, it can be transferred to any MarqMetrix Raman system. We took our glucose model and applied it to a fourth AIO, where we can now track glucose concentration in real-time. You can see in the graph below; the spikes represent points at which the bioprocess has been fed more glucose. Over time, the glucose levels drop, and once reach a minimum value, it is time to feed the bioprocess and ensure the process remains under control.

The solution we provide through the combination of our AIO hardware and data science tools allows companies to make actionable decisions to better manage their processes. Glucose monitoring is just one application where modeling can deliver a valuable solution.

To learn more about applying data science to real-world applications, be sure to subscribe to the MarqMetrix YouTube channel. You can watch a video on glucose modeling by clicking below: