Inline Raman spectroscopy is a powerful analytical technique that has found numerous applications in the downstream oil and gas industry. One of the key advantages of Raman spectroscopy is its ability to perform non-destructive analysis, making it an ideal technique for real-time monitoring of various processes. Inline Raman also provides valuable information about the chemical composition and properties of samples, making it useful for monitoring processes and identifying contaminants.

Inline Raman spectroscopy is particularly useful in this regard as it allows for continuous monitoring of the process stream without the need for sample preparation. In this blog post, we will discuss how to use inline Raman spectroscopy in downstream oil and gas, and outline the steps required to add this technique to your process.

Step 1: Determine Your Requirements

The first step in adding inline Raman to your downstream oil and gas applications is to determine your requirements. This includes understanding the type of samples you will be analyzing, the desired measurement parameters, and the environmental conditions in which the Raman system will operate.

Some key considerations include:

- Sample type: Raman spectroscopy is suitable for the analysis of both liquids and gases. Site integration considerations such as fluid process conditions and piping modifications should be defined to allow for selection of probe interface.

- Measurement parameters: Consider the specific parameters you need to measure, such as chemical composition, concentration, and physical properties. This will help determine the appropriate Raman system configuration and spectral range.

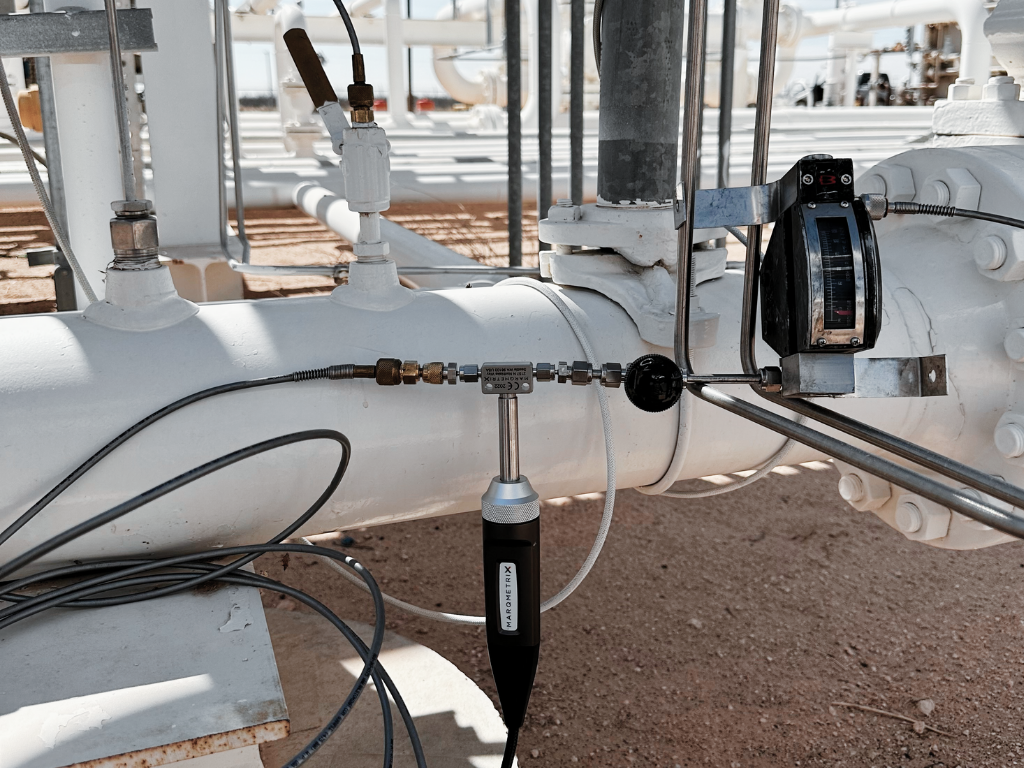

- Environmental conditions: Inline Raman systems may be exposed to harsh environmental conditions, such as high temperatures and pressures, corrosive fluids, and hazardous gases. Ensure that the Raman system is designed to withstand these conditions. The MarqMetrix All-In-One, for example, is available in a C1D2 enclosure, making it safe to use in hazardous environments.

Step 2: Select a Suitable Raman System

Once you have determined your requirements, the next step is to select a suitable inline Raman system. When selecting a system, consider the following factors:

- Spectral range: Ensure that the system can measure the spectral range required for your analysis.

- Sampling interface: Inline Raman systems typically use a fiber-optically connected probe to interface with the process stream. Consider the size and design of the probe to ensure it is compatible with your process conditions.

- Sensitivity and resolution: These parameters determine the detection limit and the ability to resolve closely spaced spectral features. Consider the expected concentrations and complexity of your samples.

- Robustness and reliability: Inline Raman systems must be designed to withstand the harsh environmental conditions of oil and gas applications. Consider the materials of construction, sealing mechanisms, and protection against shock and vibration. Also consider whether the Raman analyzer is factory-calibrated, which can save significant time and money in the long run.

Step 3: Integrate the Inline Raman System into Your Process

The final step is to integrate the Raman system into your process. This involves installing the fiber-optic probe into the process stream and connecting the Raman system to the control system. Some key considerations include:

- Installation location: The probe should be installed in a representative location of the process stream and accessible for maintenance.

- Site Integration: Power and applicable site utilities will need to be available to integrate the Raman system. Communications cabling will need to be connected between your DCS/SCADA network and the Raman system.

- Calibration: Raman systems that require recalibration cannot continue to take measurements while they are being recalibrated. A factory calibrated Raman system can help you get started immediately by enabling out of the box installation directly in your process. The MarqMetrix All-In-One is factory calibrated and measurements can be correlated to the relevant ASTM standards.

- Data analysis: The Raman system should be configured to provide real-time data analysis and feedback to the control system. This may involve developing customized software or algorithms to interpret the Raman spectra. MarqMetrix offers core models to help refineries to certify gasoline blends, analyze naphtha pretreats, identify sulfur peaks, analyze CO, CO2, and oxygen level concentrations.

MarqMetrix Inline Raman for Downstream Applications

Adding inline Raman to downstream oil and gas applications can provide valuable insights into process monitoring and control. The MarqMetrix All-In-One Raman analyzer is a robust and reliable solution that meets the requirements for inline Raman in downstream oil and gas applications.

Sample Type: The All-In-One can analyze a wide range of sample types including liquids, gases, and solids. MarqMetrix probes enable TouchRaman measurements via BallProbes, continuous flow measurements with FlowCell, and contactless analysis with the Proximal BallProbe line.

Measurement Parameters: The All-In-One measures key parameters such as chemical composition, concentration, octane rating, and vapor pressure. It provides real-time analysis and feedback to the control system, allowing for rapid response to changes in the process.

Environmental Conditions: The All-In-One system is designed to withstand the harsh environmental conditions of oil and gas applications. It has a rugged design that includes a stainless-steel probe and a hermetically sealed optical system, which protects against dust, moisture, and corrosive fluids.

Spectral Range: The All-In-One covers a spectral range of 100-3250 cm-1, making it suitable for a wide range of applications. It provides high sensitivity and resolution, allowing for the detection of low concentrations and the resolution of closely spaced spectral features.

Integration: The All-In-One is easy to integrate into existing processes. You can move the All-In-One in without moving other equipment out due to its small footprint. The system is also compatible with a range of sampling interfaces, including immersion probes, flow cells, and insertion probes.

Conclusion

The MarqMetrix All-In-One is the ideal solution for adding inline Raman to downstream oil and gas applications: its robust design, high sensitivity, and real-time feedback make it a valuable tool for monitoring and controlling processes, while its easy integration and customization ensure it meets specific requirements. Learn more about the All-In-One here.